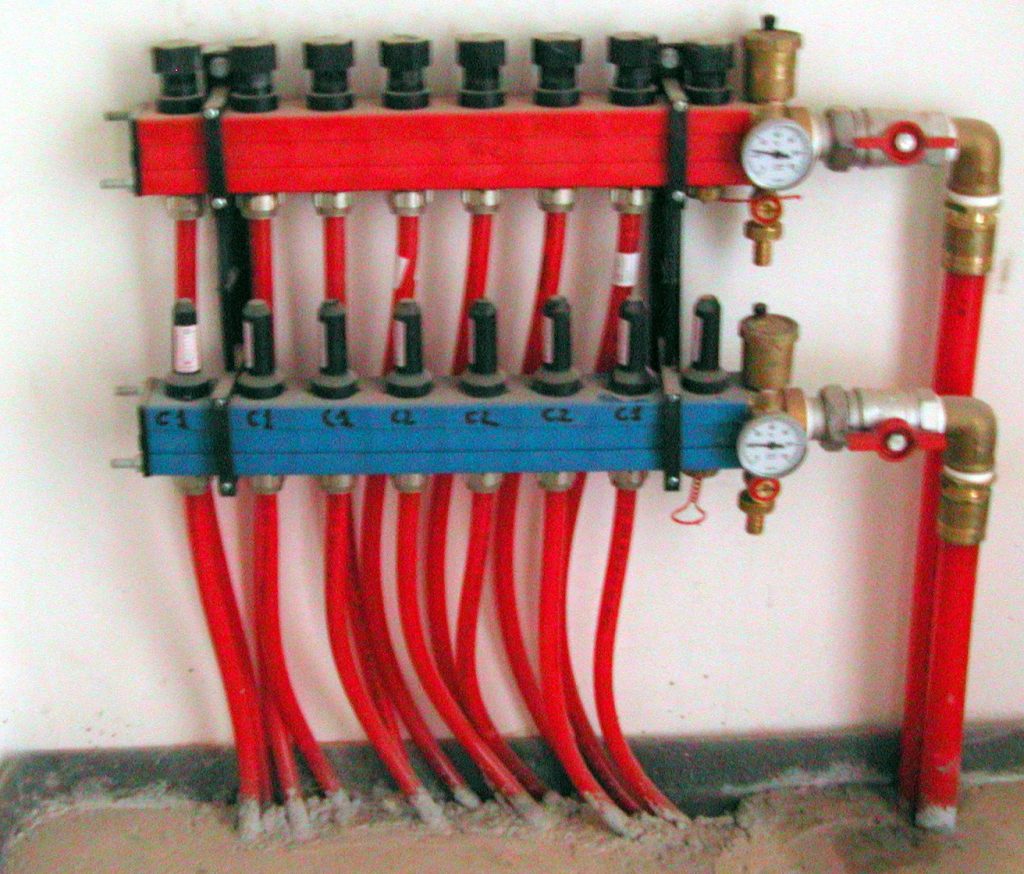

PEX (or crosslinked polyethylene) is part of a water supply piping system that has several advantages over metal pipe (copper, iron, lead) or rigid plastic pipe (PVC, CPVC, ABS) systems. It is flexible, resistant to scale and chlorine, doesn’t corrode or develop pinholes, is faster to install than metal or rigid plastic, and has fewer connections and fittings.

- Flexible PEX tube is manufactured by extrusion, and shipped and stored on spools, where rigid plastic or metal piping must be cut to some practical length for shipping and storage. This leads to several advantages, including lower shipping and handling costs due to decreased weight and improved storage options.

- PEX plumbing installations require fewer fittings than rigid piping. The flexible tubing can turn 90 degree corners without the need for elbow fittings, and PEX tubing unrolled from spools can be installed in long runs without the need for coupling fittings.

- Attaching PEX tube to fittings does not require soldering, and so eliminates the health hazards involved with lead-based solder and acid fluxes; PEX is also safer to install since a torch is not needed to make connections..

- PEX resists the scale build-up common with copper pipe, and does not pit or corrode when exposed to acidic water.

- PEX is much more resistant to freeze-breakage than copper or rigid plastic pipe.

- PEX tubing does not transfer heat as readily as copper, and so conserves energy.

- Water flows more quietly through PEX tube, and the characteristic “water hammer” noise of copper pipe systems is virtually eliminated.

- PEX plumbing installations cost less because:

- PEX is less expensive than copper pipe.

- Less time is spent running pipe and installing fittings than with rigid pipe systems.

- Installing fewer fittings reduces the chances for expensive callbacks.